Our Product - Adhesive bonded anodized aluminum

「TAF AD」

It maintains high reliability compared to conventional background processing.

Home >> Products >> TAF series >> TAF AD

What's TAF-AD

TAF AD is a special Alumite treatment with adhesion bonding base which maintains high reliability as compared with conventional ground treatment, which enables reduction of environmental burden and liberalization of lead time.

By using TAF AD, it is also possible to improve base performance and adhesion without using adhesive. The possibilities can be expanded, such as improving the value-added new product and product production process design.

Adhesion

Adhesion has an image of gluing, and many cases are thought to be a low strength bonding method. It is true that welding can not be overcome by comparing with stress, but high strength can be demonstrated at a place where bonding area can be earned. Moreover, bonding of dissimilar materials is possible, and it has characteristics such as not requiring high temperature at the time of bonding. . Applications and technical fields subject to aluminum / resin bonding systems are very diverse and are often used for applications such as reduction of the weight of the structure, improvement of strength and reliability of the joint portion, improvement of productivity, cost reduction is. These are required to have excellent adhesion strength and adhesion durability to withstand harsh operating conditions, and surface adhesion of aluminum (aluminum) is an important key for adhesion durability of aluminum. For example, when painting on aluminum, most paints will cause problems without surface treatment.

Product life cycle

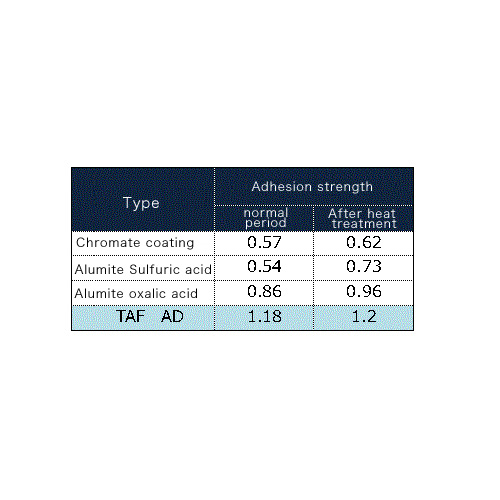

Compared with conventional chromium oxide film formation treatment and sulfuric acid anodization treatment, the TAF AD treatment has a value much higher than the adhesion strength, and there is no deterioration in adhesion strength even after heating at 150 ° C.

Product life cycle

When using an ordinary sulfuric acid anodic oxide film as a substrate for painting or adhesion, since the adhesion strength of the under-layer is lost due to a temporal change called natural pore sealing of the film, immediately (at least within one week) Although it is known that you have to proceed to the next step of painting and bonding. On the other hand, the film treated with TAF AD has a characteristic of maintaining good adhesion strength even if it has been processed for more than 1 year after treatment, which is a great practical merit.

Why it has High adhesion

High adhesion in TAF AD treated aluminum alloys is thought to be demonstrated by the resin penetrating into the porous layer of an anodized film with appropriately controlled pore size and anchoring effect. For this reason, it is expected to be deployed in various applications as a powerful method for directly bonding various resins without using an adhesive and preparing an aluminum alloy-resin composite material.

Case of Use

- 01. High heat dissipation aluminum printed circuit board base

- 02. Sealing material of chemical processing apparatus Bonding base

- 03. Various combinations such as bonding of cloth and aluminum are possible.

- 04. Others for forming aluminum resin composite material

・Base of painting or coating

→Improvement of coating film adhesion, no binder required

・Base of adhesion, aluminium to aluminium or different material

→Improvement of adhesive strength

Other aluminum and resin composite materials etc. You can use it in various fields.