Our Product - Black colored Heat-resistant anodized aluminum

「TAF TR BK」

Black Alumite which does not come out color even at high temperature of 350 ℃

Home >> Products >> TAF series >> TAF TR BK

What's TAF-TR BK

TAF TR BK is Heat-resistant, UV-resistant black Alumite treatment which does not crack or discolor even under high temperature of 350℃or in the environment of ultraviolet rays.

Matte black Alumite with Heat resistant and UV-resistant (TAF TR SBK) is also possible by pretreatment that gives low reflectivity.

By changing from conventional surface treatment to TAF TR BK, it is possible to improve performance. Recently, It is increasing the number of major companies review the operation of surface treatment technology, and the demand for surface treatment is increasingly diversifying and varying. It is expected to be deployed in various applications as a surface protection film with high cost performance that can be used in high temperatures, instead of usual Alumite treatment and high cost vapor deposition.

※There is also [TAF TR SBK] of matte (low reflection) specification.

Difference

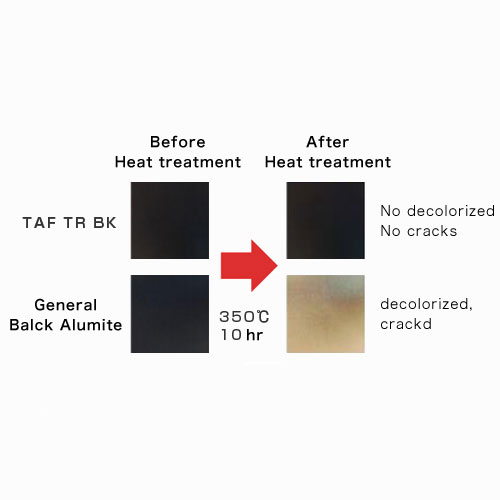

As usual black Alumite, when exposed to heat or exposed to ultraviolet rays or sunlight for a long time, the dye in the coating micro pores is decomposed and decolorized. In addition to the color tone, cracks (cracks) and coating missing occur due to the stress caused by the difference in coefficient of linear thermal expansion from the base material, resulting in loss of surface protection function. However, TAF TR BK does not discolor / decolorize, nor does it crack, even if it is heat treated at 350℃.

Heat resistance / UV resistance

Although ordinary black Alumite treatment depends on the material and film thickness of the base material, discoloration and cracking occur when heated at about 150℃., and when it exceeds 250℃., it completely decolorizes, the coating completely peels off Sometimes it happens. TAF TR BK is also durable to 350℃ heating test, there is no discoloration or cracking due to outdoor or ultraviolet irradiation. (Heat resistance test example 180℃. × 2000 hours, 350℃. × 10 hours and others)

Hardness of coatings

The film hardness tends to be different depending on the material. In the case of processing to A5052, it is possible to obtain excellent hardness as high as HV450, whereas general hard Alumite is HV 300 (according to JIS standard requirement).

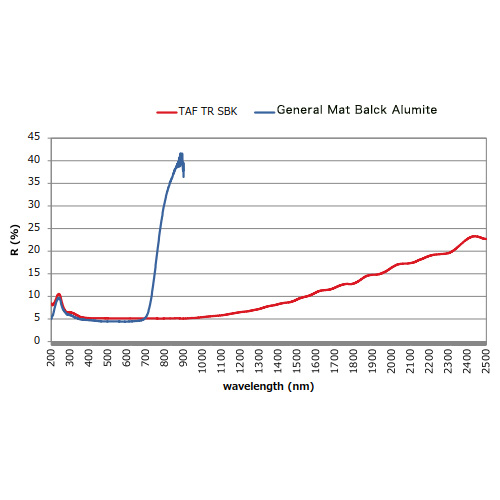

TAF TR SBK - Reflectance (Low reflectivity)

There is TAF TR SBK of matte low reflection specification as derivative processing of TAF TR BK. TAF TR SBK is optimal for optical parts (camera and light source equipment) used in high temperature environments. - Moreover, TAF TR SBK maintains low reflectance in a wider wavelength range (outside visible light) than general matte black Alumite.

Case of use

- 01. Prevention of contamination of foreign materials in semiconductor manufacturing equipment

- 02. Wear reduction of sliding partner's resin

- 03. Improvement of optical component slidability

- 04 Improvement of corrosion resistance of hard Alumite coating

- 05. Jig / heat treatment equipment used at high temperature

- 06. Stray light prevention by improving heat resistance of optical parts

- 07. Appearance parts to be used at high temperature

- 08 Improvement of heat resistance of parts to be cleaned at high temperature

- 09 Improvement of UV resistance of light source device

・It is possible to maintain black color under high temperature. No cracks or peeling occurred

→ Maintain low reflectance, prevent stray light, maintain dimensional accuracy

・It can be used outdoors

・Ideal for precision optical parts, sensors, exterior parts, etc. for cameras and light sources used at high temperatures

・It can be used for LED lighting parts and heat sinks