Our Product - Heat-resistant anodized aluminum

「TAF TR」

Ultra-hard Alumite which does not crack even at high temperature of 350℃.

Home >> Products >> TAF series >> TAF TR

What's TAF-TR

TAF TR is an ultra-hard Alumite treatment that does not crack even at high temperatures of 350℃, making it possible to use aluminum parts in high temperature range.

By changing from conventional surface treatment to TAF TR, it is possible to improve the performance, and it is also possible to reduce weight by changing from stainless steel material to "aluminum alloy + TAF TR treatment". In recent years, the number of major companies actively conducting survey and review of surface treatment technology has increased, and as the demand for surface treatment is increasingly diversified, even at high temperature, instead of surface treatment such as anodizing treatment or high cost vapor deposition, It is expected to develop into various applications in the future as a surface protective film with high cost performance that can be used.

Difference

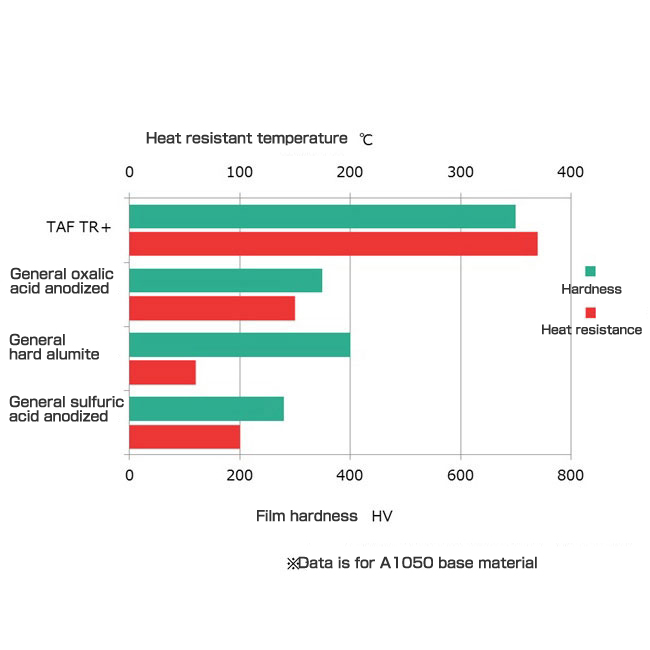

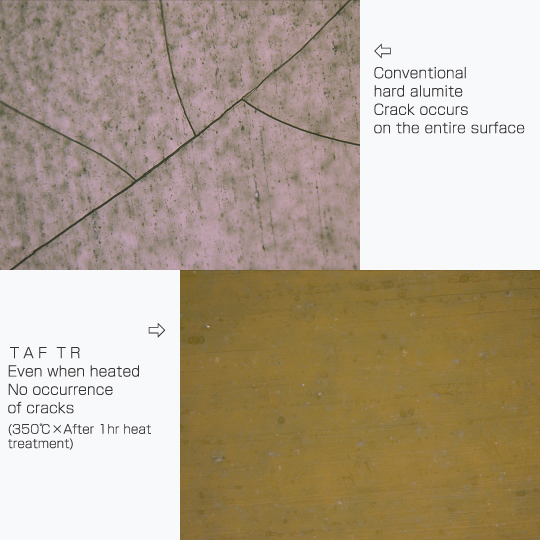

The feature of TAF TR is "crackless" and "heat resistance" anyway. For ordinary hard Alumite, cracks (cracks) occur after Alumite treatment because of its manufacturing conditions. However, since hard Alumite has been used in the past when the hardness and abrasion resistance of the film is required, cracks are not often seen as problematic. . It is also known that cracks are generated due to the stress caused by the difference in the linear thermal expansion coefficient between the Alumite and the aluminum alloy as the base material when used in a high temperature range of 100℃. or more It is. When a crack occurs, the aluminum alloy as the base material is exposed, and in the worst case the Alumite film peels off, completely losing the function of surface protection. Therefore, conventionally, surface treatment in the case of using aluminum alloy parts at 100℃. or higher is dealt with by selecting heat-resistant plating treatment or vapor deposition, or by making the material itself made of stainless steel or resin It was. . Meanwhile, Alumite treatment and use of aluminum alloy have advantages in terms of processing cost, adhesion to a base material, mechanical dimensional accuracy, weight reduction, heat conduction and the like, and in particular, insulation impartation, blackening, reflection In applications such as preventing, improving heat dissipation, improving wear resistance, heat resistant Alumite treatment technology is strongly required. In such a situation, [TAF TR] was developed by our company as hard Alumite which does not crack even at high temperature and has high heat resistance.

Heat-resistant

The heat resistance of TAF TR is 350℃, and cracks will not occur if it is lower than 350℃. (Excluding "high withstand voltage / high corrosion resistant specification" below)

※ Heat resistance was evaluated by the presence or absence of cracks after the furnace was turned off and cooled down to room temperature after holding the test piece held at room temperature in an electric furnace maintained at a predetermined temperature (350℃) for 1 hour It is.

Hardness/Abrasion resistance

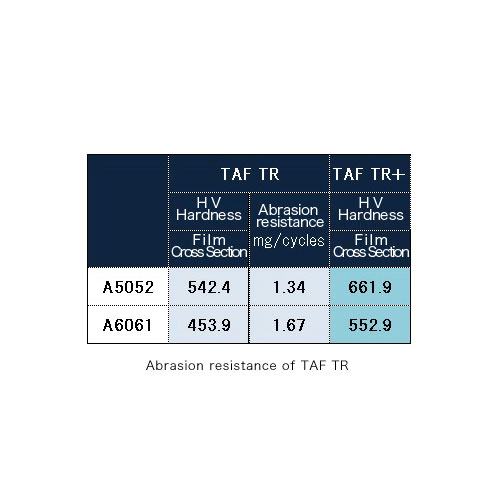

In the Vickers hardness test Hv 540, special treatment, TAF TR + Hv 650 Alumite has an extremely hard surprising value (depending on alloy material).

With respect to wear resistance, when the surface of the part becomes hot due to frictional heat with the mating member, if the hard Alumite is ordinary, the film peels off, it is damaged greatly, it corrodes from the crack Although various problems directly related to the wear resistance deterioration arise, TAF TR has high crack resistance and it is thought that such a problem hardly occurs.

Roughness

Compared with general hard anodized film, TAF TR film has smooth film and roughness, so it can improve product accuracy and sliding performance.

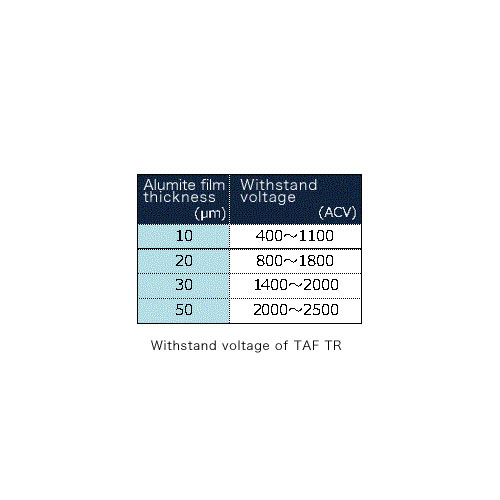

Voltage resistance

Due to the property of "crackless", TAF TR is superior to general hard Alumite in withstand voltage, and dielectric breakdown voltage (between film and base) is around 2.5 kV at high withstand voltage specification (50 μm) I will.

Case of use

- 01. Prevent contamination of foreign matter by film peeling to semiconductor manufacturing equipment etc.

- 02. Heat resistant insulating film to IC inspection jig

- 03. Improvement of component slid-ability

- 04. Jig / heat treatment equipment used at high temperature

- 05. Improvement of wear resistance and airtightness of hydraulic equipment (prevention of ingress from cracks)

- 06. Function can be imparted such as coating film adhesion and lubricity, if necessary

- 07 High heat dissipation insulating substrate Substrate

- 08 Improvement of corrosion resistance of hard Alumite coating (prevention of corrosion from cracks)

- 09 Wear reduction of sliding partner (resin etc.)

- 10. Black specifications include heat sinks and industrial heat resistant optics (such as high temperature cameras)

・Prevention of particle generation due to cracks

→ Parts for semiconductor devices

・Improvement of dielectric breakdown voltage and heat dissipation

→ Substrate for insulating layer of electronic parts / substrate

・Improvement of sliding and abrasion resistance

→ Sliding parts such as cylinders, pistons and rollers

Heat resistance / UV resistance / low reflection!→ TAF TR Black »